The Journey of Marble from A Quarry to Structure

December 9, 2021 AdminFrom yesteryears to the present, natural stones have been adorning this world with their beauty. Whenever it comes to adding beauty & class to any architectural piece, natural stones emerge as the best choice of people. Though there are different types of natural stones available to choose from, one choice that has a long-standing history of enticing people with its magic is marble, and particularly white marble. From the majestic Taj Mahal to the leaning tower of Pisa, marble exhibits its own character.

Among all natural stones, marble is an extremely practical building material and also a visually entrancing surface. But just like the enticement of marble stone, it is also interesting to know how it is extracted from the earth’s crust and how it takes shape later.

So, let’s get to know more about this wonderful natural stone in the following section.

What is Marble?

Marble is considered a unique stone. Its colors and design structures are outstanding and exclusive. However, it doesn’t begin its voyage this way. It takes years for marble to look the way it does. A majority of things need to be set appropriately under the work of various divisive forces. It is only at the culmination of a lengthy process that we can take the stone from the earth to admire its attractiveness, turning it into a marble countertop, marble tile, or backsplash that stays with us for years.

The Formation of Marble

Marble stone takes shape from limestone by encountering extreme heat and pressure below the earth’s crust. These high-intensity forces cause the limestone to change its texture and character. This process is known as recrystallization. The fossilized materials present in the limestone and their uncommon carbonate ore, recrystallize and result in big-size, coarse particles of calcite. The scums present in the limestone during the recrystallization process influence the mineral arrangement of the marble that comes out. The minerals that emerge from these contaminations award marble a wide range of colors. The purest marble that contains calcite is white marble. Marble with rich amounts of hematite is of red color. A yellow color marble contains limonite is whereas a marble that contains serpentine is of green color.

Here are some quick facts about marble:

- It is not easy to split the marble into equal size sheets and this is why marble is mined in an extremely careful manner

- The use of explosives for mining the marble blocks is not done as this may shatter the rock

- The ancient use of marble is found in various structures in Greek

- The Italian artist Michelangelo used marble in various sculptures.

- Smaller pieces of some marble variants are crinkled and used as abrasives in soaps and other items

Marble Mining

It takes several thousands of years for the marble to take shape. This is why it is considered an uncommon, distinctive material. Marble is primarily composed of calcium carbonate.

There are many marble quarries in India, particularly in the states like Rajasthan, Haryana, Gujarat, Sikkim, Maharashtra, West Bengal, and others.

The exact size of the marble block and the extract strategies depend on the location of a particular quarry. However, marble quarrying is typically carried out in vertical cuts but this is not mandatory.

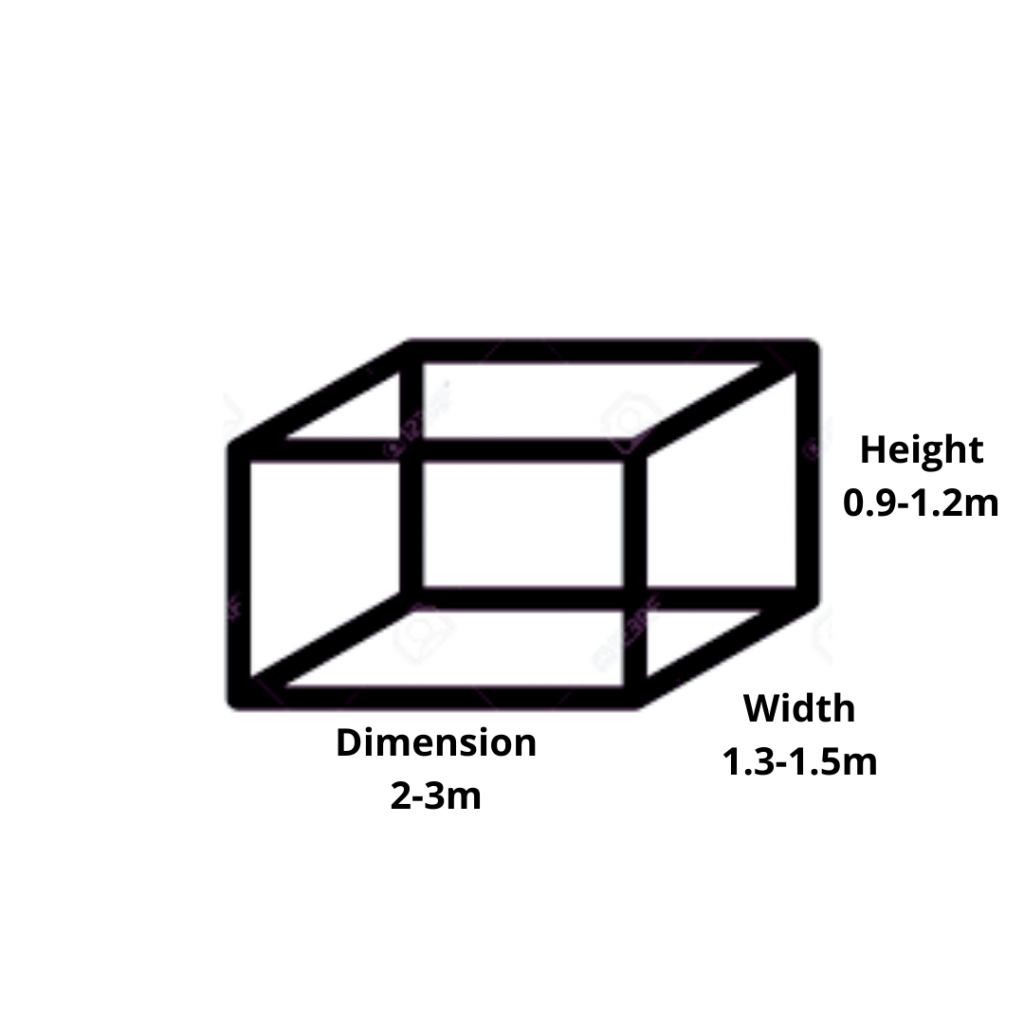

The extracted marble block is comprised of 6 corresponding sides. Each side weighs between 6 and 15 tonnes. The dimension hovers between 2.2 and 3 meters. Width falls in the range of 1.2 to 1.5 meters, with 0.9 to 1.2 meters in height.

Transport and unloading of blocks

Once the marble blocks have been mined from the quarry, these are taken by heavy trucks to the manufacturers for further processing. At each processing unit, the blocks are unloaded and categorized in the blocks plot before being cut.

Due to their dimensions and enormous weight, marble blocks are handled with cranes and specialized machinery, both during loading/ unloading and processing.

Marble cutting

In most scenarios, marble blocks are cut using a multiwire cutter or block cutter. Usually, big size blocks are cut in a multiwire cutter whereas small blocks are cut in block cutters. The selection of a particular cutting machine is done in order to reduce the wastage of stone while getting precisely sizes marble slabs.

Multiwire Cutting

The marble blocks are exposed to the cutting machine through a platform. The machine is comprised of several diamond wires that cut the block in a vertical direction. It takes nearly 8 hours to a common-sized marble block.

Block Cutting

In the extracted blocks are uneven, using this type of cutting method involves high cost. This is where block cutters are used. Block cutters tend to have a big diamond saw blade which also cuts the blocks in a vertical course. These cuts are done in both directions.

At the same time, an additional horizontal saw blade cuts the bands after the right vertical depth has been attained.

Marble Polishing

Once the white marble slabs are processed, the next stage involved the polishing of the same. There are different types of finishing that are applied on the marble surface. Some of the popular finishes are:

- Polished: This marble finish is meant to augment the marble’s glossy effect and color by giving it an even, glossy surface.

- Honed: It awards the look of a matt, gloss-free surface. Its major difference with the rough marble is that this finish eliminates all cutting marks.

- Bush hammering: It results in a bristlier finish enabling better hold, which makes it perfect for outdoor applications.

- Antique: It provides marble with a rough, shine-free feature similar to natural wear and tear.

- Lepatora

- Brushed

Once the finishing is done, marble slabs are stored in the warehouse for further transportation to local projects or other countries. India is known to be a leading source of a wide variety of marble. Be it white marble, black marble, green marble, or any other color, the easy availability of marble makes Indian marble suppliers in huge demand all across the globe.